HAND FILE HACKS

HAND FILE HACKS

Hi!

This is Kodo with Kodoan. You can find out more about me at

kodoan.com.

That’s

K O D O A N DOT COM.

Files

don’t get a lot of coverage in woodworking but they are quite

useful – especially for dialing in joints and inlays. I use hand

files on a daily basis for making specialty woodworking products such

as these Japanese Shakuhachi flutes.

Sharp,

accurate hand files are a necessity for getting the blowing edge

(called utaguchi) perfectly flat and for creating the dove tail like

inlay you see here. This particular style is called Kinko ryu.

Here

are my three most used files that are many years old (I’d say about

ten years old or maybe older) and yet, they don’t show signs of

needing being replaced anytime soon.

The

biggest reason is the sheaths that protect the “teeth” of the

files. Even though these files are used on seasoned bamboo, hardwood

and other things like buffalo horn, ivory and silver, they still have

years of life left as long as they go back into their sheaths after

use.

I

cringe every time I see a woodworker (or metal worker for that

matter) reach into a bucket, a toolbox or a drawer and rummage around

before pulling out a battered file with dull, rolled teeth covered in

dings. I mean, I GUESS they MIGHT work but it’s doubtful you’re

gonna get much accuracy with them. I’d rather use a file that’s

sharp with accurate edges. A sheath ensures your hand file will do

what you ask, when you ask it – efficiently and accurately.

Just

as important as a sheath is a good handle. A good handle is

enjoyable to look at AND to pick up. It creates a seamless interface

between the user and the tool. It allows you to put your

concentration where it should be – on what you are doing –

instead of focusing on maintaining a hold on your tool. A

good handle is one that fits YOUR hand – not anyone else’s.

For this reason, good quality hand files are usually purchased

without a handle. The assumption is that this is for someone that

knows what they’re doing and only they can make the best handle for

them.

A

bad handle, or worse, no handle at all, forces

you to maintain a white knuckle “death grip” on the end of your

hand file which quickly leads to fatigue, cramping and loss of

concentration and accuracy in your work. THIS is the environment in

which mistakes are easily made. At the least, it will lead to the

marring or

damage of

your work. At it’s worst, it will lead to the

marring or

damage of

you!

For

custom made handles, you

can go old school and just use a green branch from a tree in your

back yard like this one with a piece of copper plumbing pipe as a

ferrule. This one took me all of about 5 minutes to make and is

actually my favorite both in looks and function. I simply drilled a

hole in the end

and carefully tamped in the tang. No glue or epoxy was needed

because, as the green branch dries, it shrinks down onto the tang and

locks it in place. This technique is hundreds of years old and still

a great option

today.

Even after years of use, this handle shows no sign of coming loose

anytime soon.

The

sheath for it is just some doug fir from the scrap bin. I

hastily carved out a

channel in one

piece, gave the

two pieces a

quick glue up and then

rounded

the outside.

It’s all

I’ll ever need

to keep this

hand file in good working condition for years and years.

This

handle was a small piece of maple from the scrap bin turned on my

lathe. My inspiration for it was that I had seen someone drill into

an old golf ball and glue in the tang of a rat tail file. I turned

this to be a little more ergonomic and, when it’s in my hand, it

feels almost surgically attached. I can completely forget about

holding it while I focus on what I’m using it for – which is

usually clearing out the inner bamboo nodes (called “fushi” in

Japanese) when I’m making Shakuhachi. The sheath is a piece of

scrap bamboo that fits this round file so well that, when it’s put

on, it won’t fall off at all.

This

smaller file is a triangular file that I use

for creating the dove tail like inlay the mouth piece of the

Shakuhachi that I make. It was about twice this length – which was

too long. It was difficult to be accurate with my inlays with such a

long file so I snapped it in half and cold ground the end smooth.

Now, it does exactly what I ask it to do.

The

handle was another piece of that branch that had dried out. I rough

turned it on my lathe and drilled a hole in the end like the other

one. I didn’t even bother with a ferrule on this one. Years later

and….so far so good!

The

sheath is another piece of bamboo. This one is quite thick –

unusually thick for bamboo. It fits nicely and keeps it

well protected.

So,

to sum it up, if you want to get the most out of your files, I

suggest making a custom handle that fits YOUR hand. It can be as

easy as a branch off of a tree or a lathe turned piece of hardwood.

In

addition to a handle, make a sheath to keep your file sharp for

accuracy and longevity.

It

has been said that the meaning of life is to learn and then share.

In

classical martial arts, the Masters say, “no matter where you

start, strive to always get better”.

I

hope this video helps you on your path.

0

The Alex Jones Show

The Alex Jones Show

KEEPER

KEEPER

RT

RT

Timcast IRL

Timcast IRL

Nick J Fuentes

Nick J Fuentes

Redacted News

Redacted News

Life_N_Times_of_Shane_T_Hanson

Life_N_Times_of_Shane_T_Hanson

TheQuartering

TheQuartering

Shin

Shin

Styxhexenhammer666

Styxhexenhammer666

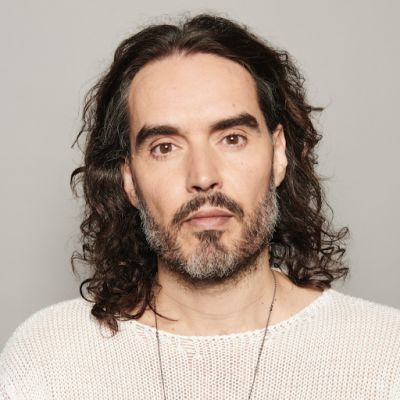

Russell Brand

Russell Brand

The Muslim Skeptic

The Muslim Skeptic

KnowMoreNews

KnowMoreNews

Log in to comment

A quick down and dirty way to make a good file handle is to drill a hole in a golf ball and hammer the tang into the ball. he mentions it in this video and I can tell you this method works great for a good handle

As an Engineer I class good quality files as essential tools. Being used on wood and/or bone your files will probably outlast you.

For your inlay work have you considered riffles? They are mostly used for final hand finishing of moulds, or were before CNC and LASER polishing.

BTW a triangular file should be called a three-square as they are usually used for filing the corners of a square hole square, also I think the name sounds better.